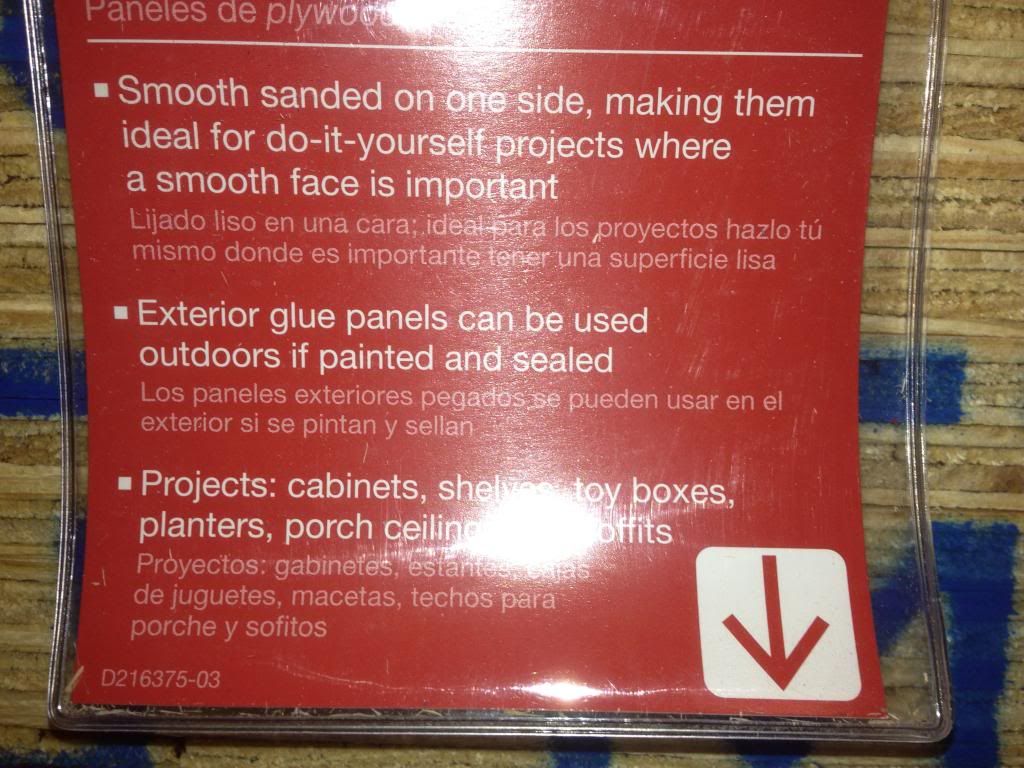

I'm going to do this again, because I want to help, not tell you what you have to do to your boat. If you have become a Marine Engineer, or need the head trip, do what you want, it is after all your boat. Home depot does tell you which plywood has exterior glue and which ones shouldn't be exposed to moisture.

1/2" is more than enough. If you're looking at weight you could use 3/8" It's all getting covered and that's where the real strength is. Anything more is just adding weight to your boat. These are sanded on one side, although I have no problem with voids. A little bondo fills them right up, and strength isn't an issue. A little flash problem herfe the price is $19, not $10.

You may have to pass on the top couple sheets to get a flat one, but it's getting screwed down to the stringers and will be flat aftre that.

Cut them to fit and then give the pieces a couple coats or resin and Acetone 50/50. Remember to double the MEKP.

I have use bi-axial cloth with mat to cover it with, but when Red did Okie-Dokie, he used Roveing with mat. I like that it's really strong. This is a "One shot" deal. Wet the plywood down, lay in the fiberglass that you pre-cut and go over it with resin to fully wet it down. That's it.

You should paint it, or my choice gel-Coat it.

Remember your original floor and transom lasted 40-50 years and wasn't built this well from the factory. Glues have improved, resins have improved, and you're soaking the plywood in resin on both sides. It will outlast you, ok, it will outlast me and after that yer on yer own. If you have more money than you know what to do with, give it to your local food-shelf, If you just need a "feel good head trip" spend the money on plywood.